An Example Of Synthesis Reaction

What is a Synthesis Reaction?

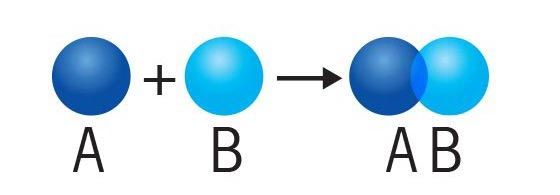

Synthesis reactions are reactions that occur when two unlike atoms or molecules interact to course a different molecule or compound. Nearly of the fourth dimension, when a synthesis reaction occurs, energy is released and the reaction is exothermic. Yet, an endothermic outcome is also possible. Synthesis reactions are ane of the major classes of chemical reactions, which include unmarried deportation, double deportation, and combustion reactions.

Complex Synthesis Reactions

Many synthesis reactions are far more than complex than the above reaction: A + B → C. For example, organic synthesis reactions may involve more than ii unlike molecules, and mixtures of products can occur along with unreacted starting materials. Intermediate molecules may form that can lead to the formation of byproducts. In addition, depending on how the two colliding reactant molecules orient, both the desired product and byproducts may class - which may event production purity.

There are diverse types of synthesis reactions. For example, nucleophilic and electrophilic add-on and substitution reactions are broad reaction types that yield innumerable examples of synthesis reactions.

When two or more than reactants combine to class a more circuitous molecule, the composition of the final reaction mixture is dependent on the weather at which the reaction is carried out.

Factors Influencing Successful Synthesis Reactions

A successful synthesis reaction maximizes the creation of desired molecules and minimizes byproduct molecules. A thorough understanding of reaction kinetics, mechanism, and effect of reaction variables are keys to successful synthesis reactions.

- Quality of Reactants, Reagents, and Catalysts -The quality and purity of starting materials and stable sources/vendors of those materials is key to successful, reproducible synthesis reactions and processes.

- Reaction Conditions -Since synthesis reactions are sensitive to reaction parameters, such every bit temperature, pressure, agitation rate, and dosing rate, precise and accurate control of these variables is crucial to the successful outcome. EasyMax chemical synthesis reactor provides automated parameter control, accuracy, and precision of reaction parameters.

- Reaction Equipment -In the pharmaceutical industry, nigh synthesis reactions run in batch mode. The physical configuration of EasyMax reactors are an comeback over the classic round bottom flask due to surface expanse and agitation efficiency considerations. Continuous flow processes are chop-chop becoming more than ofttimes used, and ReactIR engineering science accommodates the real-time analysis of continuous flow and batch syntheses.

- Reaction Kinetics -A thorough understanding of reaction rates are crucial to ensure optimized product yield and minimum byproducts. Through data-rich experiments, ReactIR simplifies and speeds the measurement of kinetic factors in synthesis reactions.

- Product Isolation/Purity -Though separation techniques are a mainstay for product isolation and purity, an understanding of reaction variables to reduce the presence of impurities that may be hard to separate for product is important. By optimizing reaction variables, ReactIR with EasyMax aid impurity reduction. As of import, a thorough understanding and control of crystallization via ParticleTrack and ParticleView technology is critical to ensuring purity and ease of isolating desired products.

- Rubber -Commercially-important chemical science requires lab-to-plant protocols that provide optimized yield, acceptable impurity profiles, and safe functioning. ReactIR advances reaction calibration-up past elucidating the effects of reaction variables on overall synthesis functioning. Reaction calorimetry ensures safe reactions from screening through calibration-up to process past measuring heats of reaction. ReactIR in situ analytics minimizes exposure of scientists and technicians to toxic chemicals and potentially chancy reactions by eliminating grab sampling for offline analysis. When offline assay is required, EasySampler provides automated, in situ sampling and dilution of samples for HPLC, eliminating worker exposure.

Workstations for Automated and Unattended Synthesis Reactions

Individually, or every bit an integrated chemical workstation, these tools provide disquisitional back up for better synthesis reactions:

- Chemical Synthesis Reactors (EasyMax and OptiMax)

Unattended, precise command and data drove of reaction weather condition

- FTIR Spectrometers and Raman Spectrometers

Real-fourth dimension tracking and profiling of key reaction species equally a office of reaction time to aid kinetics and mechanistic investigations

- Automated, Inline Sampling (EasySampler)

Unattended, representative sampling of reactions when offline assay is required

- EasyViewer

In-situ video microscopy of particle/droplet size and shape to apace increase purity and yield during work-up - Powerful Analytical Software (iC)

Integrates data streams for comprehensive understanding and data direction

Replace Manual Synthesis Reaction Steps

With Automated Synthesis Workstations

Smart chemic synthesis reactors, combined with unattended dosing and automated sampling, provide a simple and safe way to precisely control reaction parameters and obtain reaction information unattended and around the clock.

- Automatically record recipe steps, experimental weather condition and analytical data making it like shooting fish in a barrel to repeat experiments and share findings with colleagues

- Run reactions at any temperature from -xc°C to 180°C without an ice bathroom, oil bath, or heating mantle

- Configure parameter controls (such as temperature, dosing, sampling, and stirring) separately for each vessel

- For multi-parameter analysis, including Design of Experiments (DoE) studies, precise and reproducible control assist to yield accurate results

- Interchangeable sleeves, drinking glass reactors, and tubes provide flexibility to synthesize at volumes from 0.v mL to 1000 mL

Enhance Understanding of Synthesis Reactions with FTIR & Raman

Gain in-depth data about reaction kinetics, mechanisms, and pathways. Support safe and optimized scale-upward of chemistry. ReactIR and ReactRaman spectrometers provide in situ, real-time monitoring of chemical reactions for batch and continuous flow syntheses.

- Develop real-time trending profiles for key reaction species: reactants, intermediates, products, and byproducts

- Obtain information-rich information for traditional kinetic assay or Reaction Progress Kinetics Analysis (RPKA) methods

- Monitor reactions where removing a sample for offline assay is difficult, impossible or undesirable – low temperature, elevated temperature/pressure, viscous, toxic reagents, highly energetic reactions, air/moisture sensitive, transient intermediates

- Investigate primal stages of a reaction or procedure, such every bit reaction offset, consecration menses, aggregating, conversion, and endpoint. Detect reaction stalling or upsets

- Rapidly determine the event of variables on reactions

- Investigate the broadest range of chemical reactions with ReactIR and ReactRaman. Choose the best technique to match specific chemistries and reaction variables.

- Enhance understanding of solution crystallization processes with ReactRaman for monitoring crystallographic form and polymorphism, and ReactIR for investigating solvent furnishings and supersaturation.

View a Live eDemo from your work or habitation office on your schedule.

Automated Sampling For Synthesis Reactions

EasySampler is an automated, unattended technology delivering representative and reproducible samples. The probe-based engineering science has a micro-pocket, which takes samples at any given time, quenches in-situ and dilutes for ready to analyze offline samples.

EasySampler supports reaction agreement by providing samples on need. Sampling is performed under reaction atmospheric condition, making it truly representative. The samples, in one case collected and time stamped, tin can be analyzed via offline analytical methods and the result integrated dorsum into the information stream. An boosted value lies in the increased information quality through automatic and seamless data collection. The increased accuracy and precision of automated sampling provides higher quality versus manual sampling.

Improve Synthesis Reactions with Fewer Experiments

Combine PAT Data with Advanced Modeling

Reaction Lab uses Process Analytical Technology (PAT) information to accurately model the event of a range of variables simultaneously, thereby revealing the best set up of operating weather for synthesis reactions. The response of the reaction to the effect of varying specific parameters and weather condition is determined, and response surfaces generated give insight into product yield/impurity tradeoffs. Furthermore, the information from PAT and Reaction Lab facilitate a greater understanding and back up for proposed reaction mechanisms and permit processes to be more than effectively designed based on this insight.

Synthesis Reaction Examples

Automated Chemistry Solutions for Synthesis Reactions in Industry-Related Publications

Below is a option of publications where automated solutions are used for synthesis reactions.

- Yang, H. S., Macha, L., Ha, H. J., & Yang, J. W. (2021). Functionalisation of esters via 1,iii-chelation using NaOtBu: mechanistic investigations and synthetic applications.Organic Chemistry Frontiers,8(1), 53–lx. https://doi.org/10.1039/d0qo01135e

- Millward, Chiliad. J., Ellis, E., Ward, J. W., & Clayden, J. (2021). Hydantoin-bridged medium ring scaffolds by migratory insertion of urea-tethered nitrile anions into effluvious C–N bonds.Chemical science,12(6), 2091–2096. https://doi.org/10.1039/d0sc06188c

- Jurica, J. A., & McMullen, J. P. (2021). Automation Technologies to Enable Data-Rich Experimentation: Beyond Design of Experiments for Procedure Modeling in Late-Phase Process Development.Organic Process Enquiry & Development,25(2), 282–291. https://doi.org/10.1021/acs.oprd.0c00496

- Shi, Y., Prieto, P. Fifty., Zepel, T., Grunert, S., & Hein, J. Due east. (2021). Automatic Experimentation Powers Data Science in Chemistry.Accounts of Chemical Research,54(3), 546–555. https://doi.org/ten.1021/acs.accounts.0c00736

- Connor, C. Thousand., DeForest, J. C., Dietrich, P., Do, North. One thousand., Doyle, K. Thousand., Eisenbeis, South., Greenberg, Due east., Griffin, S. H., Jones, B. P., Jones, K. N., Karmilowicz, K., Kumar, R., Lewis, C. A., McInturff, Due east. 50., McWilliams, J. C., Mehta, R., Nguyen, B. D., Rane, A. M., Samas, B., . . . Webster, 1000. E. (2020). Development of a Nitrene-Type Rearrangement for the Commercial Route of the JAK1 Inhibitor Abrocitinib.Organic Procedure Research & Development,25(3), 608–615. https://doi.org/10.1021/acs.oprd.0c00366

- Glace, A. W., Cohen, B. M., Dixon, D. D., Beutner, G. L., Vanyo, D., Akpinar, F., Rosso, 5., Fraunhoffer, Chiliad. J., DelMonte, A. J., Santana, Due east., Wilbert, C., Gallo, F., & Bartels, W. (2020). Safe Scale-upwards of an Oxygen-Releasing Cleavage of Evans Oxazolidinone with Hydrogen Peroxide.Organic Process Research & Development,24(2), 172–182. https://doi.org/10.1021/acs.oprd.9b00462

- Benkovics, T., McIntosh, J., Silverman, Due south., Kong, J., Maligres, P., Itoh, T., Yang, H., Huffman, Thousand., Verma, D., Pan, W., Ho, H. I., Vroom, J., Knight, A., Hurtak, J., Morris, West., Strotman, North., Murphy, G., Maloney, K., & Fier, P. (2020). Evolving to an Ideal Synthesis of Molnupiravir, an Investigational Treatment for COVID-19.ChemRxiv. Published. https://doi.org/ten.26434/chemrxiv.13472373.v1

- Mennen, S. M., Alhambra, C., Allen, C. Fifty., Barberis, G., Berritt, S., Brandt, T. A., Campbell, A. D., Castañón, J., Cherney, A. H., Christensen, G., Damon, D. B., Eugenio de Diego, J., García-Cerrada, S., García-Losada, P., Haro, R., Janey, J., Leitch, D. C., Li, L., Liu, F., . . . Zajac, M. A. (2019). The Evolution of High-Throughput Experimentation in Pharmaceutical Development and Perspectives on the Future.Organic Process Inquiry & Development,23(vi), 1213–1242. https://doi.org/10.1021/acs.oprd.9b00140

- Wang, K., Han, Fifty., Mustakis, J., Li, B., Magano, J., Damon, D. B., Dion, A., Maloney, Thou. T., Post, R., & Li, R. (2019). Kinetic and Data-Driven Reaction Assay for Pharmaceutical Procedure Development.Industrial & Engineering Chemical science Inquiry,59(6), 2409–2421. https://doi.org/10.1021/acs.iecr.9b03578

Featured Commodity: Understanding α,β-Unsaturated Imine Formation

Determine Relative Reaction Rates and Farther Mechanistic Agreement

Calow, A. D. J., Carbó, J. J., Cid, J., Fernández, Eastward., & Whiting, A. (2014). Understanding α,β-Unsaturated Imine Formation from Amine Additions to α,β-Unsaturated Aldehydes and Ketones: An Belittling and Theoretical Investigation.The Journal of Organic Chemistry,79(11), 5163–5172.

In previous work, the researchers had reported a catalytic method to synthesize chiral γ-amino alcohols via in situ generation of α,β-unsaturated imines. They stated that there was a lack of kinetic or mechanistic studies regarding the relative 1,two- versus one,4- improver of main amines to α,β-unsaturated aldehydes and ketones. To farther this understanding, the researchers used in situ ReactIR spectroscopy along with NMR studies and DFT calculations, to better narrate the addition of chief amines to α,β-unsaturated aldehydes and ketones (1,ii- vs 1,4-addition) and examine the relative rates of these reactions.

ReactIR data showed that when benzylamine was added to crotonaldehyde, 1,2- addition resulted exclusively whereas when benzylamine was added to methyl vinyl ketone, 1,4- addition resulted exclusively.

An Example Of Synthesis Reaction,

Source: https://www.mt.com/es/en/home/applications/L1_AutoChem_Applications/L2_ReactionAnalysis/synthesis-reactions.html

Posted by: jamesfiect1953.blogspot.com

0 Response to "An Example Of Synthesis Reaction"

Post a Comment